Essential for the operation of such a device is the overlap between the electron trajectory and the photon beam. Therefore the undulator modules will be equipped with Beam Position Monitors (BPM) and correctors in order to observe and correct the electron trajectory.

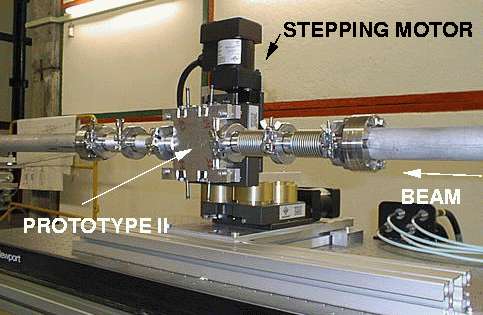

A new microwave concept is considered to design a BPM

capable of detecting beam position with a resolution of a few micrometer.

The monitor system is based on ridged waveguides coupling by small slots

to the magnetic field accompanying the electron beam. The beam position

will be measured in a X-band receiver. A

first prototype of this

monitor was built and tested at the

CLIC

Test Facility at CERN. An improved design

leading to a new prototype was tested at

the S-band Test Facility in Hamburg.

In 1999 one module of the undulator has been equipped with 10 such monitors

including electronics and brought into operation.

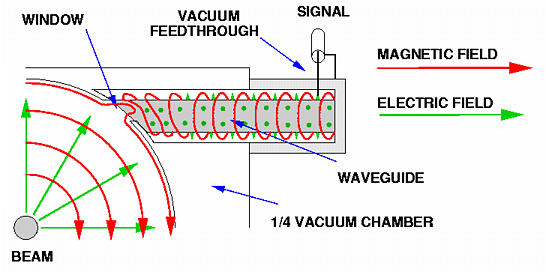

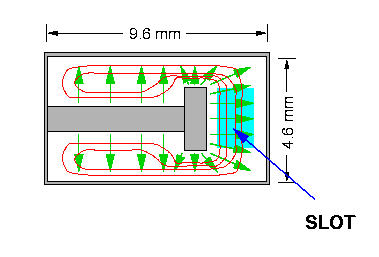

Sketch of the coupling mechanism. The magnetic field accompanying

the electron beam bends through the coupling window into the waveguide

and excites there a mode which travels through the waveguide and will be

linked at the end into a coaxial system. The mode's amplitudes depend on the

position of the beam and are therefore suitable to derive precise beam positions.

The profile shape of the waveguide is one of the key

points in the design. At first it must be designed in a way that a sufficient

amount of the field can couple. Secondly, the cut-off frequency should be below

the beam pipe cut-off to avoid reflecting waves from travelling through

the beamline.  In our design the ridged waveguide serves both constraints.

In addition, the ridge enhances the magnetic field density at the coupling

slot and causes thus an overlap between the magnetic field of the

beam and of the waveguide's fundamental mode. Furthermore, it lowers the

cut-off frequency to the desired value well below the beam tube cut-off

frequency.

In our design the ridged waveguide serves both constraints.

In addition, the ridge enhances the magnetic field density at the coupling

slot and causes thus an overlap between the magnetic field of the

beam and of the waveguide's fundamental mode. Furthermore, it lowers the

cut-off frequency to the desired value well below the beam tube cut-off

frequency.